Forklifts play an important role in material handling, improving productivity and ensuring workplace safety. Without forklifts, performing various tasks in the manufacturing, construction, logistics and warehousing industries would be more challenging or even impossible.

If you’re interested in purchasing or leasing a new forklift, you may ask yourself an important question — which is better, a gas or electric forklift? Below, we answer this important question by looking at these two options’ key differences and similarities.

How Electric and Gas Forklifts Work

Electric forklifts are powered by electricity from rechargeable batteries, which store electrical energy and convert it into mechanical energy to operate the forklift. Electric forklift batteries are typically lead-acid or lithium-ion.

Compared to an electric forklift, how does a gas forklift work? Gas forklifts use internal combustion engines, typically powered by gasoline or propane. These engines convert the chemical energy stored in the fuel into mechanical energy, which gives the forklift power.

Benefits and Considerations of Electric Forklifts

Before adding an electric forklift to your fleet, you should be aware of the following advantages and considerations.

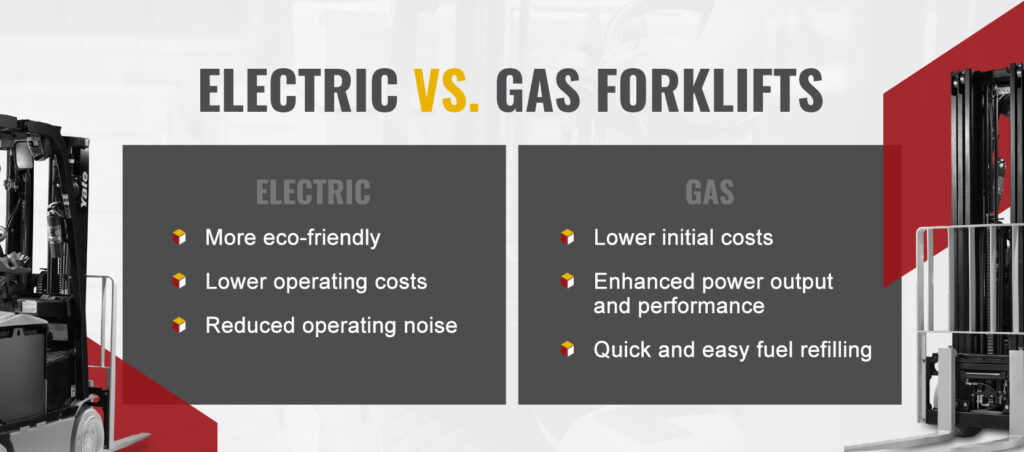

Electric forklifts have many advantages, including:

- More eco-friendly: These machines are battery-powered and produce zero emissions, which is a notable benefit for businesses prioritizing sustainability. Just one electric forklift can make a positive dent in a company’s carbon footprint.

- Lower operating costs: Electric forklifts have lower operational and maintenance costs. This is primarily due to their simpler design, which requires less frequent servicing and fewer replacement parts compared to internal combustion forklifts. Electricity is often cheaper than gasoline or diesel fuel, leading to savings over time.

- Reduced operating noise: Electric forklifts are quieter than gas-powered machines. This feature is ideal in areas where noise pollution is a concern. It also helps teams communicate better and more clearly during operation.

Some important considerations of electric forklifts include:

- Higher upfront costs: Electrical forklifts tend to be more costly to purchase because of their advanced technology and battery systems. Many businesses find that the long-term savings in operating and maintenance costs can offset this initial expense.

- Battery-limited operation: Relying on battery power can limit operational time, depending on the battery’s load capacity. If an electric forklift is only partially charged before operation, teams may have to delay their tasks while they wait for the battery to charge. Fortunately, proper charging techniques and a charging schedule can help manage this problem.

- Sensitive to extreme weather conditions: Electric forklifts tend not to perform optimally in extreme temperatures — lithium-ion batteries in particular experience capacity reduction when temperatures drop. This issue can be a hindrance when trying to work through cold weather.

Benefits and Considerations of Gas Forklifts

Like electric forklifts, gas forklifts have their own share of advantages and potential downsides.

Gas forklifts have several benefits:

- Lower initial costs: Gas-powered forklifts tend to be more affordable due to their simpler technology, making them a great option for companies with budget constraints. These forklifts have been used widely across industries for many years, so various price points are available, and replacement components are easier to find.

- Enhanced power output and performance: Gas forklifts have a heavy lifting capacity and are often ideal for moving heavy loads and working on rugged or uneven terrain.

- Quick and easy fuel refilling: When refueling a gas forklift, you can simply replace the empty cylinder with a new one. This less time-consuming process can contribute to higher productivity on the job site.

If you’re considering adding a gas forklift to your fleet, you’ll also want to note the following considerations:

- Environmental impact: Gas forklifts produce emissions like nitrogen oxides and carbon monoxide, which can contribute to air pollution.

- Not ideal for indoor operations: These machines aren’t suitable for indoor operations because of their emissions.

- More costly to operate and maintain: High fuel prices can lead to higher operating costs. These machines also typically require more maintenance than electric options, including air filter replacements, oil changes and overall engine servicing.

Differences in Cost and Maintenance for Electric and Gas Forklifts

Electric and gas forklifts operate differently, so the cost and maintenance of each option also vary. Here are some key points to be aware of when considering your choices:

Initial Purchase Costs

Electric forklifts tend to have a higher upfront purchase price than gas forklifts. This is because of the greater cost of battery technology and electric motors. The price difference will also depend on factors such as model specifications and features.

Maintenance Requirements

Maintenance for electric forklifts is generally less intensive because there are fewer moving parts and no need for oil changes. However, battery maintenance, including regular checks on charging cycles and water levels, is essential for optimal performance. Gas forklifts need more frequent servicing, which can lead to higher maintenance costs.

Operational Costs

Gas forklifts require fuel to operate. Gasoline and propane prices can fluctuate, leading to higher operating costs. In comparison, electric forklifts generally have lower operating costs due to the cost of electricity compared to the cost of gasoline or propane.

Safety Considerations

There are a few safety factors to keep in mind when operating and caring for electric forklifts:

- Sulfuric acid: This acid is present in lead-acid batteries and is highly dangerous, so it’s essential to wear protective gear when handling this battery type.

- Maintenance: Implement a standard maintenance plan for forklifts to help reduce the chances of accidents.

- Charging technique: Establish charging stations away from a lot of foot traffic to help reduce the chances of electric shocks, fumes exposure and other risks.

For gas forklifts, the safety protocols to keep in mind include:

- Carbon monoxide exposure: Operate the forklift in a well-ventilated environment to avoid exposure to exhaust fumes.

- Refueling procedure: Avoid refueling near heat sources or confined spaces. In addition, only authorized and trained individuals should handle refueling.

- Preoperation inspections: Before operating, thoroughly inspect key components such as fluid levels and hydraulic cylinders, looking for leaks, excessive vibration and other damage or wear. If the forklift doesn’t pass the preinspection, don’t operate it.

How to Choose the Right Forklift

To select the right forklift, consider your business’s unique requirements. A few key factors to consider include:

- Performance needs: A gas forklift can be a great option if you need a forklift to lift heavy loads consistently. Electric forklifts work well in confined spaces for lighter loads.

- Work environment: Electric forklifts are great for businesses that primarily operate in indoor environments. They’re safer, cleaner and generally more practical. Consider a gas forklift if your operations tend to be outdoors or require rugged terrain.

- Short- and long-term costs: Electric forklifts generally have a higher upfront cost. However, these machines have lower operating and maintenance costs in the long term. Gas forklifts are often more affordable to purchase or rent but require higher maintenance costs.

Find Your New Forklift at Bohl Equipment Co.

There’s no one-size-fits-all approach to choosing a forklift. To choose the right forklift, assess your requirements, including loading capacity, budget and operational environments, to determine which is most suitable for your fleet.

If you need further assistance, Bohl Equipment Co. can help. We understand that every business has individual needs, so we offer different options to help you find the machine that suits your team best. Whether you’re looking to expand your fleet or want to understand more about different capabilities, our knowledgeable team can assist.

Bohl Equipment Co. has over 100 years of experience in equipment parts and services, and we offer a wide range of forklifts from the industry’s leading brands. Find a location near you to get started, or simply contact us today to find the right forklift for your business.